Unveil! ——A certain refractory material testing center surprisingly uses such technology to make every refractory brick "capable of being fired and resistant"

In the field of high-temperature industry, the quality of refractory materials directly affects the safety and efficiency of production. The Sinosteel Luoyang Institute of Refractories Research Co., Ltd. Quality Inspection and Testing Center relies on cutting-edge technology and digital means to create a full process, high-precision testing system, providing the industry with "hardcore" quality assurance!

1. Accurate component analysis, ensuring quality first

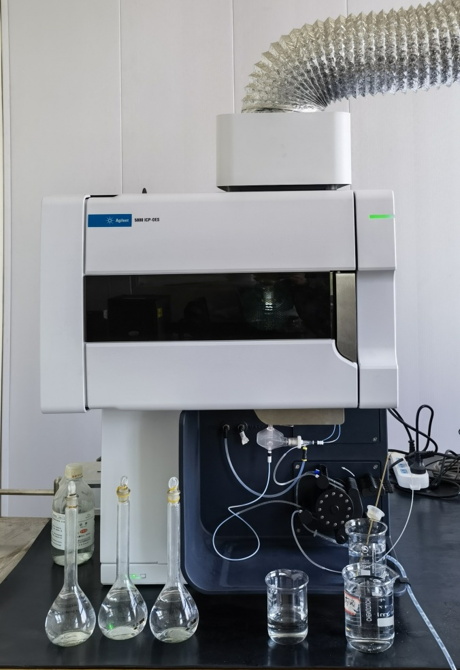

By using X-ray fluorescence spectroscopy (XRF) and inductively coupled plasma (ICP) technology, rapid and accurate detection of material composition is achieved. The elemental analysis range covers the entire periodic table, with a detection accuracy of up to 0.01%, ensuring that the quality of raw materials is foolproof.

XRF

ICP

2. Comprehensive performance evaluation, simulating extreme conditions

By using a high-temperature flexural testing machine and a thermal shock stability tester, the thermal shock resistance, corrosion resistance, and flexural strength of materials are accurately measured in an ultra-high temperature environment of 1600, providing reliable data support for different industrial scenarios.

Thermal shock test furnace

3. Microscopic high-definition scanning to see the true meaning of the material

Using a scanning electron microscope to take a high-definition photo of the material, combined with a super focused microscope as a magnifying glass, even the nanoscale microstructure can be seen clearly, truly achieving the transparency of material properties.

XRD

XRD

Choose us and use the toughest technology to safeguard safety under every degree of high temperature!